Table of Contents

- What a tcpel Pellet Machine Can Do For You

- Why Do People Even Make Pellets?

- How Do These Machines Actually Work?

- What Kinds of Things Can a tcpel Pellet Machine Handle?

- What Should You Look For in a tcpel Pellet Machine?

- What Good Things Come From Using a Pellet Machine?

- Where Do People Typically Use a tcpel Pellet Machine?

- How Do You Keep Your tcpel Pellet Machine Running Smoothly?

What a tcpel Pellet Machine Can Do For You

When you consider the many ways to transform raw materials into something more useful, more compact, or perhaps even more valuable, the idea of a pellet machine often comes up. These clever pieces of equipment, like what a tcpel pellet machine might offer, take loose stuff and press it into little, dense shapes. This process, you know, makes things much easier to store, to move around, and even to use for different purposes. It's a way of taking something that might be bulky or difficult to manage and giving it a brand new form, one that is, in some respects, far more convenient.

Think about all the bits and pieces that might otherwise go to waste, or simply take up too much room. A machine designed to make pellets, a tcpel pellet machine, for instance, can gather these items and turn them into something neat and tidy. It’s a pretty neat trick, really, turning what seems like a collection of disparate parts into a uniform product. This ability to create something so organized from something so loose is, you know, quite a helpful thing for many different kinds of operations, big or small, that need to handle a lot of material.

So, if you’re wondering how to get more out of your raw stuff, or how to manage waste better, or even how to create a new product from what you already have, looking into what a tcpel pellet machine can achieve might just be the answer. It’s all about making things more efficient and, you know, getting the most bang for your buck out of whatever materials you’re working with. It's a straightforward idea, but the practical results can be, well, quite significant for folks who need to handle a lot of material.

Why Do People Even Make Pellets?

You might wonder, why go through the trouble of turning things into pellets? What's the big deal? Well, there are quite a few good reasons, actually. For one, when you make something into a pellet, it becomes much denser. This means that a big pile of loose material, like sawdust or animal feed, can fit into a much smaller space once it's in pellet form. This is pretty useful for storage, you know, because you don't need as much room in your barn or warehouse, which saves on space and, in turn, on costs, too it's almost a given.

Another big reason is how easy pellets are to transport. Imagine trying to move a huge amount of loose hay or grain versus moving the same amount in neat, compact pellets. The pellets are less messy, they don't blow away as easily, and you can fit more of them onto a truck or into a container. This makes shipping things around, you know, much more straightforward and, in some respects, less expensive in the long run. It's about getting more product moved with less effort, which is a pretty good deal for anyone involved in moving goods.

Then there's the consistency. When you have materials in pellet form, they're all pretty much the same size and shape. This is super helpful if you're using them in a machine that needs a steady flow, like a furnace that burns wood pellets for heat, or an automated feeder for livestock. The uniform size means the machine can handle them better, and you get a more even result, which is, you know, quite important for consistent operations. It helps things run smoothly, without the hiccups you might get from uneven, loose material, so that's a definite plus.

Also, making pellets can sometimes make materials safer or more effective. For example, turning animal feed into pellets can prevent animals from picking out just the parts they like, making sure they get a balanced diet. Or, for things like wood waste, turning it into pellets reduces dust and makes it less likely to spontaneously combust, which is, you know, a very important safety benefit. So, in many situations, the act of pelletizing actually improves the material itself, making it better for its intended use, which is a key consideration for many people.

How Do These Machines Actually Work?

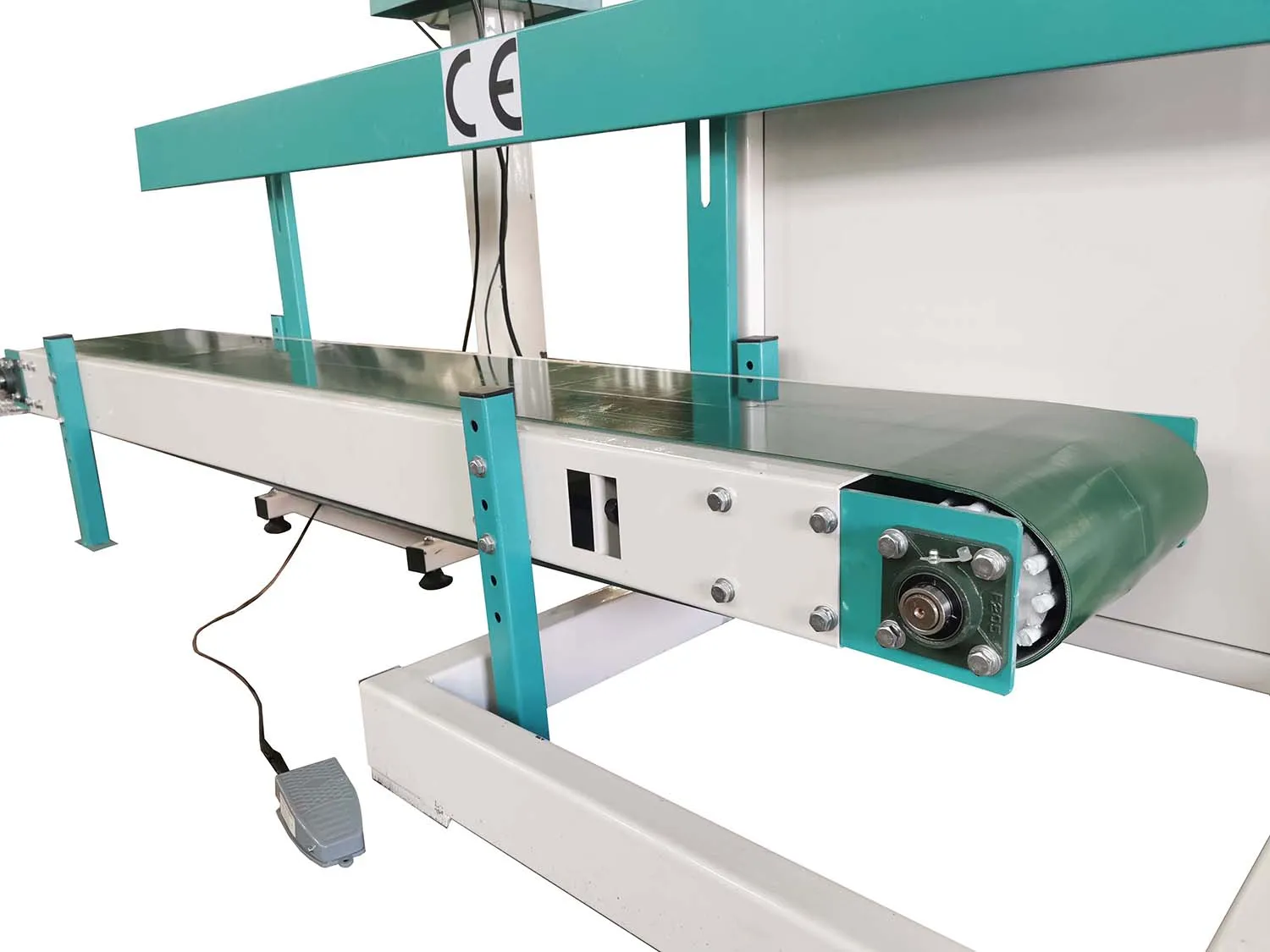

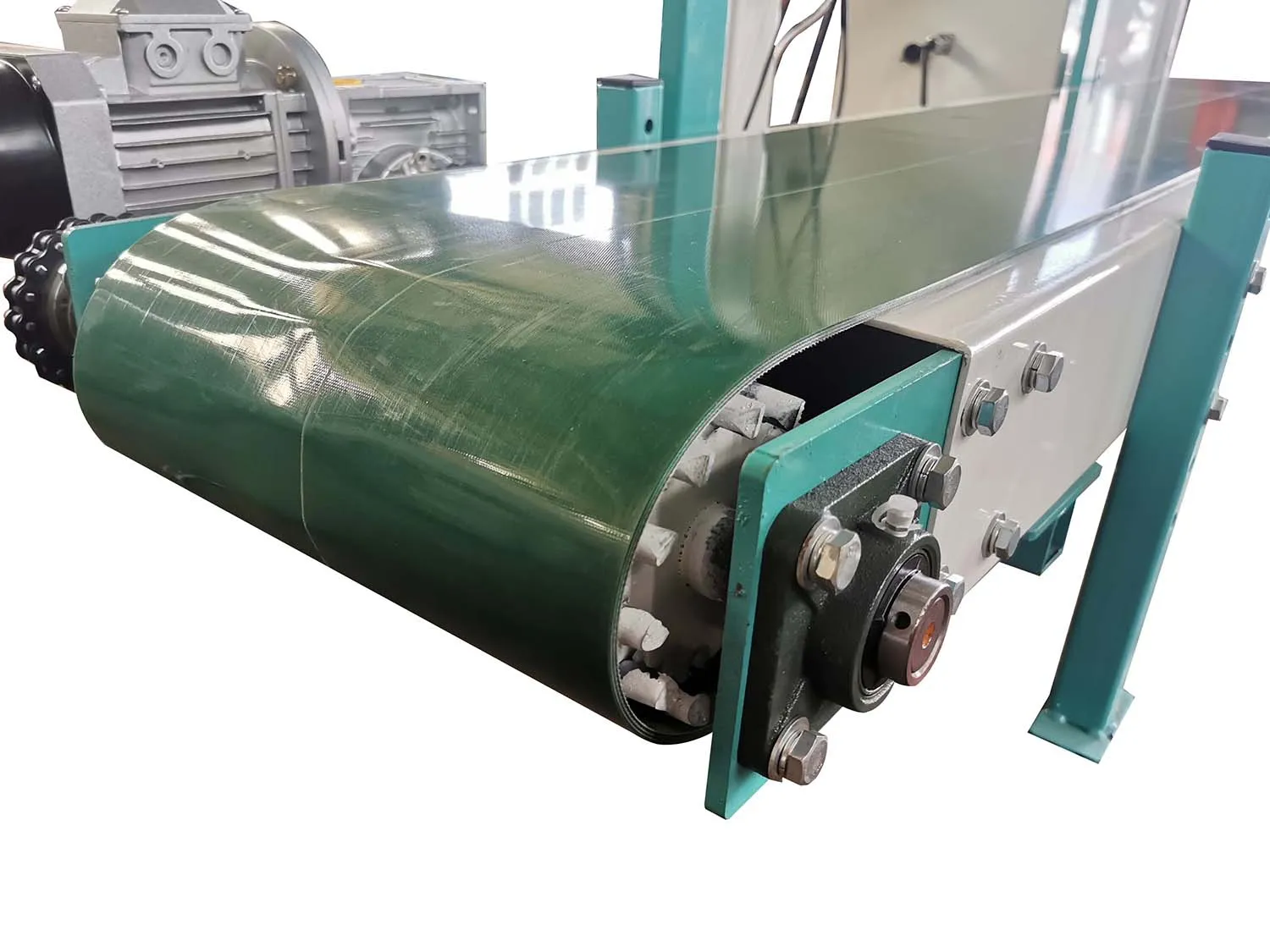

It's pretty interesting how a tcpel pellet machine, or any pellet machine for that matter, manages to turn loose stuff into those neat little cylinders. Basically, the material you want to pelletize goes into the machine. Inside, there's usually a system of rollers and a die, which is a flat plate or a ring with lots of holes in it. The rollers, you know, press the material through these holes with a lot of force. It’s a bit like squeezing toothpaste out of a tube, but on a much bigger, more powerful scale, which is actually quite clever.

As the material gets pushed through the holes, the pressure and friction create heat. This heat, along with the natural binders in some materials (like lignin in wood), helps the particles stick together. For materials that don't have natural binders, you might need to add a little something extra, like starch or molasses, to help them hold their shape. Once the material comes out of the holes, it's in the form of long strands, which are then cut to the right length by a knife or a cutter. This creates the individual pellets, which is, you know, the main goal of the whole process, so that's pretty much it.

After they're cut, the pellets are often still quite warm and a little soft. So, they usually go through a cooling process. This helps them harden up and become more durable, ready for storage or transport. Sometimes, they might also go through a screening step to remove any dust or broken pieces, ensuring you get a good, consistent product. It's a series of steps, really, from loose material to finished pellet, each part playing a role in getting that final, sturdy shape, which is, you know, quite an involved process when you think about it.

The core idea behind a tcpel pellet machine's operation is that strong, steady pressure. It's that consistent squeezing action that transforms the raw input into a denser, more manageable form. Without that sustained force, the material wouldn't bind together properly, and you'd just end up with a mess, you know. So, the engineering of the rollers and the die is pretty important for getting those perfect, uniform pellets every time, which is, in some respects, the most important part of the machine's design.

What Kinds of Things Can a tcpel Pellet Machine Handle?

It's pretty amazing the variety of materials that can be turned into pellets using a machine like a tcpel pellet machine. When most people think of pellets, they probably picture wood pellets used for heating. And yes, wood waste, like sawdust, wood chips, and even tree bark, is a very common material. Turning these forestry by-products into pellets is a fantastic way to make use of something that might otherwise just be thrown away, providing a sustainable source of energy, which is, you know, a pretty big deal for many folks.

But it doesn't stop there. Agricultural waste is another huge category. Think about all the leftover bits from farming: corn stalks, rice husks, wheat straw, even cotton stalks. These can all be pelleted. This is great for farmers who want to convert their crop residues into animal bedding, or perhaps even a source of fuel for their own farms. It’s a way of getting more value out of every part of the harvest, which is, you know, quite a smart move for anyone in agriculture.

Animal feed is also a really big one. A tcpel pellet machine could be used to make feed pellets for chickens, pigs, cattle, fish, and even pets. Pelleting animal feed makes sure that all the ingredients are mixed together properly in every bite, preventing animals from being picky eaters and ensuring they get all the nutrients they need. Plus, it's easier to store and feed out, which is, you know, a real time-saver for livestock operations, so that's a major benefit.

Beyond these, there are some other interesting uses, too. Some people pellet things like municipal solid waste, trying to turn trash into a usable fuel. Others might pellet specific industrial by-products or even certain types of plastics for recycling purposes. It really depends on the specific design of the tcpel pellet machine and what it's built to handle, but the possibilities are, you know, pretty wide open when you consider all the different materials out there that could benefit from being compacted into pellet form.

What Should You Look For in a tcpel Pellet Machine?

So, if you're thinking about getting a tcpel pellet machine, or any pellet machine for that matter, there are a few important things you'll want to consider. It's not just about picking the first one you see, you know. You want to make sure it's the right fit for what you need to do. One of the first things to think about is the capacity. How much material do you need to process in an hour or a day? Some machines are small and good for home use, while others are huge industrial beasts. You need to match the machine's output to your actual requirements, which is, you know, a pretty basic but important step.

Then there's the type of material you'll be working with. Not all pellet machines are made for all materials. A machine designed for wood pellets might not be ideal for making animal feed, and vice-versa. Some materials are harder or more abrasive, and they'll require a machine with stronger components and a more robust design. You'll want to check the specifications of the tcpel pellet machine to make sure it's built to handle your specific raw material, so that's a very important point.

Power source is another thing to think about. Do you have access to three-phase electricity, or do you need a machine that runs on single-phase power? Maybe you even need one that runs on a tractor's power take-off (PTO) if you're out in a field. The power requirements can really affect where and how you can use the machine, and it's something you need to sort out early on, you know, to avoid any surprises down the line, which is, in some respects, a practical consideration.

Maintenance and spare parts are also worth considering. Any machine that works hard will need some care and occasional replacement parts. Is it easy to get spare parts for the tcpel pellet machine you're looking at? Are there good instructions for how to keep it running well? A machine that's easy to maintain will save you a lot of headaches and downtime in the long run, which is, you know, a pretty big deal for keeping your operations smooth and efficient, so that's something to definitely ask about.

Finally, think about your budget, of course. Pellet machines come in a pretty wide range of prices. You want to find something that fits what you can afford, but also something that's going to last and do the job well. Sometimes spending a little more upfront on a better-built tcpel pellet machine can save you money on repairs and inefficiency later on. It’s about finding that sweet spot between cost and quality, you know, so you get good value for your money, which is, you know, what everyone wants, essentially.

What Good Things Come From Using a Pellet Machine?

There are quite a few really good things that happen when you start using a pellet machine, like what a tcpel pellet machine could offer. One of the most obvious benefits, as we touched on earlier, is how much easier it makes things to handle. Loose materials can be messy, dusty, and just generally a pain to deal with. Pellets, on the other hand, are clean, compact, and flow nicely. This makes loading, unloading, and moving them around a breeze, which is, you know, a real convenience for anyone working with bulk materials.

Then there's the matter of storage space. We talked about density, and it really does make a difference. If you're currently storing a big volume of loose material, converting it to pellets can free up a lot of valuable space. This can mean you need a smaller warehouse, or you can store more product in the same area. Either way, it's a pretty good win for efficiency and cost savings, you know, which is always a welcome outcome for businesses or even home users, so that's a big plus.

For those interested in sustainability, pelletizing is a fantastic option. It allows you to take waste products, like agricultural residues or wood scraps, and turn them into something useful, often a source of renewable energy. Instead of these materials just sitting in a landfill or being burned inefficiently, a tcpel pellet machine helps give them a new purpose. It's a way of closing the loop, you know, and making the most of our resources, which is, in some respects, a very responsible thing to do for the environment.

Also, the consistent quality of pellets is a huge advantage for many applications. When you're feeding livestock, you want to make sure they get a balanced diet with every mouthful. When you're burning fuel, you want a steady, predictable heat output. Pellets deliver on this consistency in a way that loose materials often can't. This leads to better performance, less waste, and more reliable outcomes, which is, you know, pretty much what everyone hopes for in their processes, so that's a definite benefit.

And let's not forget the potential for new revenue streams. If you have a lot of waste material, a tcpel pellet machine could turn that waste into a sellable product. Wood pellets for heating, animal feed, or even specialized biomass pellets can be sold to other businesses or individuals, creating a whole new source of income from something you might have previously just thrown away. It’s about seeing opportunity in what others might see as trash, you know, which is a pretty smart business move, actually.

Where Do People Typically Use a tcpel Pellet Machine?

You find pellet machines, including what a tcpel pellet machine might be, in a surprisingly wide range of places, actually. One of the most common spots is in the agricultural sector. Farmers use them a lot to make feed for their animals. This could be for cows, chickens, pigs, or even fish in aquaculture operations. It helps them manage their feed costs, make sure their animals get proper nutrition, and store feed more easily, which is, you know, pretty much essential for modern farming practices, so that's a big area.

Another very popular place is in the forestry and woodworking industries. Sawmills, furniture makers, and even just folks who cut down trees often have a lot of sawdust, wood shavings, and other wood waste. Instead of just getting rid of it, they use a pellet machine to turn it into wood pellets for heating homes or businesses. This turns a waste product into a valuable energy source, which is, you know, a pretty smart way to manage resources and create a new product, too it's almost like magic.

Beyond these big ones, you also see pellet machines in places focused on waste management and recycling. Some companies use them to process certain types of industrial waste or even specific kinds of plastics into a more manageable form for further recycling or as a fuel source. It’s all about taking something that's difficult to deal with and making it easier to handle or repurpose, which is, you know, a pretty important step in reducing our overall waste output, so that's a good thing.

And let's not forget about individuals or small businesses. Some people who have access to a lot of biomass, like farmers with crop residues or homeowners with a lot of garden waste, might invest in a smaller tcpel pellet machine for personal use. They might make their own animal bedding, their own heating pellets, or even just compact garden waste to make it easier to compost. It brings the power of pelletizing right down to a more personal level, which is, you know, quite empowering for those who want to be more self-sufficient, actually.

How Do You Keep Your tcpel Pellet Machine Running Smoothly?

Just like any piece of equipment that works hard, a tcpel pellet machine needs a bit of care and attention to keep it running well. Ignoring maintenance can lead to breakdowns and costly repairs, which is, you know, something nobody wants. One of the most basic things is regular cleaning. Material can build up inside the machine, especially around the dies and rollers. Keeping these parts clean helps the machine work efficiently and prevents blockages, which is, in some respects, a simple step that makes a big difference.

Lubrication is another key aspect. Moving parts need grease or oil to reduce friction and wear. You'll need to follow the manufacturer's guidelines for where and how often to lubricate the different points on your tcpel pellet machine. Proper lubrication helps extend the life of bearings and other components, ensuring everything moves freely and smoothly, which is, you know, pretty important for preventing premature wear and tear, so that's something to keep an eye on.

Checking and replacing worn parts is also vital. The dies and rollers, in particular, will wear down over time because of all the pressure and friction they experience. Keeping an eye on their condition and replacing them when they start to show significant wear will help maintain the quality of your pellets and the efficiency of the machine. It’s a bit like changing the tires on your car, you know; you do it before they're completely worn out to keep things safe and effective, which is, in some respects, just good practice.

Also, paying attention to the material you feed into the machine is important. Make sure it's prepared properly – usually, it needs to be the right size and have the right moisture content. Feeding material that's too wet, too dry, or contains foreign objects can damage the machine or lead to poor quality pellets. A tcpel pellet machine works best when it's given the right kind of input, which is, you know, pretty much a universal rule for any kind of processing equipment, so that's something to remember.

Finally, keeping good records of maintenance and any issues you encounter can be really helpful. This way, you can spot patterns, anticipate when parts might need replacing, and generally stay on top of the machine's health. It's about being proactive rather than reactive, which is, you know, a much better way to manage any piece of valuable equipment, ensuring your tcpel pellet machine keeps producing those useful pellets for a long time, so that's a good habit to get into.

So, we've gone over what a tcpel pellet machine does, why making pellets is a good idea, how these machines work, what materials they can handle, what to look for when choosing one, the benefits of using them, where they're typically found, and how to keep them in good shape. It's clear that these machines offer a really practical way to transform various loose materials into a more useful, manageable, and often more valuable form, making processes simpler and more efficient for many different purposes.

- Viridiana Alatriste Cause Of Death

- Grandstay Hotel Algona Ia

- Hevan

- Animal Care Center Buffalo Grove Il

- Paulos Chevrolet